History

Global Tech Co., Ltd. began operations in April of 1987 as a CLEANROOM Contractor for pharmaceutical, biotech and electronic industries both in Thailand and in the neighboring countries such as Laos, Myanmar and Vietnam.

In addition to designing and installing cleanroom system to customers, Global Tech also provide integrated facility planning to meet cGMP and GAMP compliance requirements. Global Tech is ready to provide turn-key solution with the company expertise and experience.

Turn-key Project

Design and install cleanroom system as a turn-key project starting from construction of building, HVAC & related systems, process equipments and support facilities such as purified water, gas.

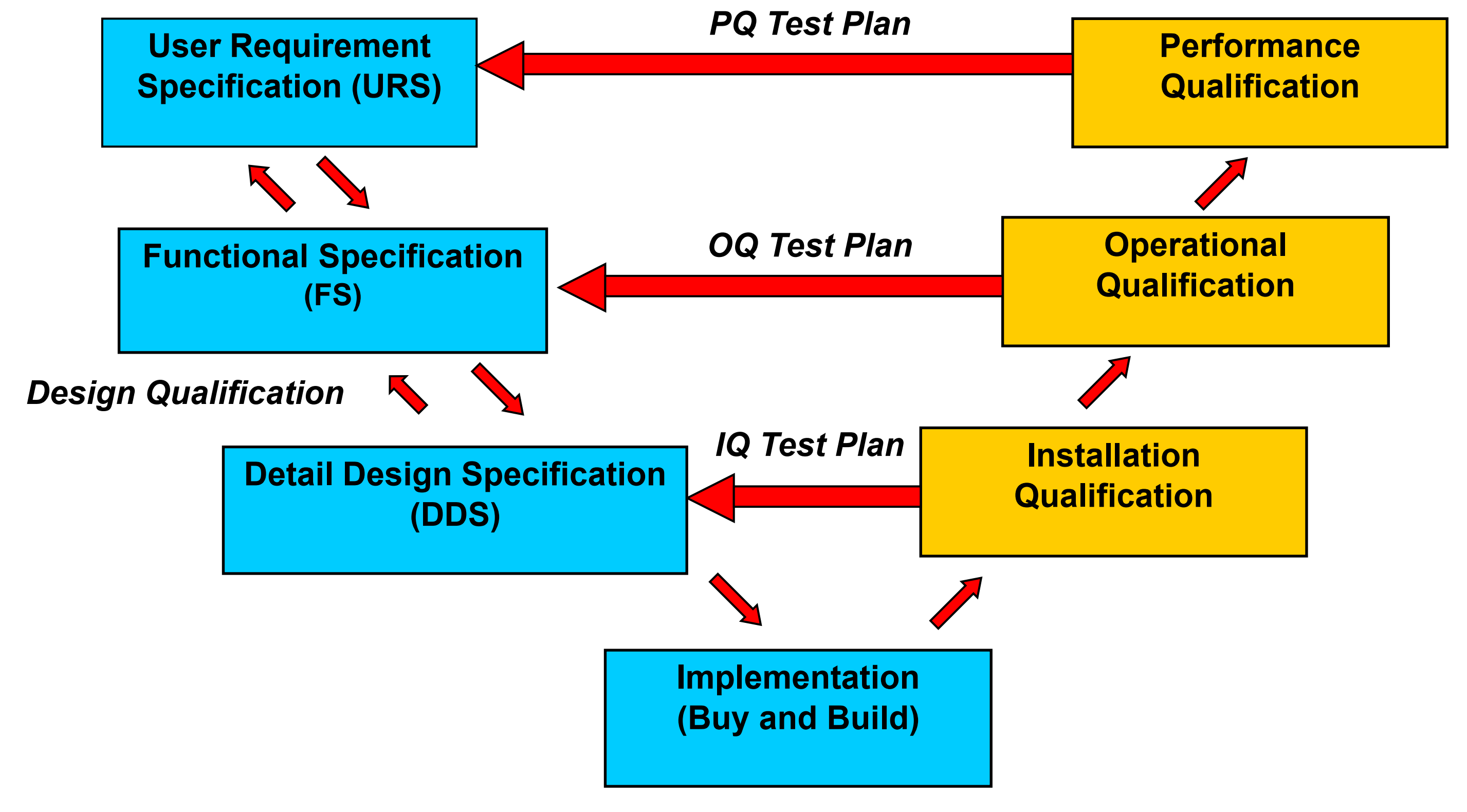

Commissioning and Qualification

Design Qualification (DQ), Installation Qualification (IQ), Operational Qualification (OQ), Performance Qualification (PQ)

Cleanroom Validation

NEBB Certified Firm for Cleanroom Performance Testing.

Service and Maintenance

After sales service and annual service contract.